FOOD APPLICATION

CEREALS

Complete systems for virtually any kind of cereal.

CPM Wolverine Proctor product a vast range of efficient, flexible, highly productive systems for cereal production. Our world-class machines combine our extensive process knowledge with our engineering expertise to bring you process equipment for the production of virtually any kind of cereal.

CATEGORY PRODUCTS

- Granola bars

- Kibbled granola

- Cornflakes

- Wheat flakes

- Bran flakes

- Multigrain flakes

- Bran sticks

- Rice crispies

- Rice bubbles

- Traditionally-cooked cereals

- Extrusion-cooked cereals

- Coextruded pillow products

- Puffed rice

- Puffed wheat

- Shredded wheat

- Shreddies

- Sugar-coated

- Sugar-frosted

- Directly-expanded face-cut products

CHECK OUT OUR

CEREALS EQUIPMENT

(SCF) SINGLE CONVEYOR DRYER/COOLER

The conveyor dryer offered by CPM Wolverine Proctor today is the result of many years of production experience. Whether it is a two-foot-wide (0.6m) unit drying an expensive pharmaceutical product or a 14-foot, 6-inch-wide (4.4m) machine producing product at a rate of 100,000 pounds per shift, the components are carefully selected to meet your production requirements.

(SCFIII) ULTRA SANITARY DESIGN SINGLE CONVEYOR DRYER/COOLER

Food industry processors have been feeling the pressure, as recent pathogen contamination outbreaks have put an even greater emphasis on equipment sanitation. CPM Wolverine Proctor’s new ultra-sanitary SCF III takes equipment design to a whole new level of cleanliness, offering you the highest level of sanitation ever provided.

MULTIPLE CONVEYOR DRYER/COOLER

Famous for gentle, uniform drying with precise climate control in a rugged, good-looking design, the Multiple Conveyor Dryer/Cooler is built to last. Up to seven conveyors can be combined with accessories in the smallest possible floor space for the most economical, efficient, and comprehensive answer to your drying needs.

JETZONE FLUIDIZED BED

High-velocity air passes through long tubes to create a bed of air, which suspends and tumbles the product as the air reflects from a solid, non-perforated conveyor. The open space between the tubes forms a chamber to settle out smaller pieces, and returns processed air for recirculation without affecting the fluidizing air jets. During fluidization, each particle is surrounded and separated from adjacent particles by the treatment air.

IMPINGEMENT OVEN

CPM Wolverine Proctor offers Impingement Ovens with the Jet-Tube, custom engineered for your specific application. Products are stationary on a moving belt or band, and air-using tubes are directed at high velocity over the items on the band.

PARA-JET NOZZLE IMPINGEMENT OVEN

CPM Wolverine Proctor’s Para-Jet Nozzle Impingent Oven uses a forced air circulation system incorporating the PARA-JET NOZZLE technology to impinge heated air directly onto the product being baked.

JETZONE FLUIDIZED BED COOLER

Jet-Tube Fluidization technique is the fastest, most uniform and efficient method of cooling the majority of particulate free-flowing products. It is ideal for dense, difficult-to-cool products.

BELT COOLER

Compact with a sanitary design, easy to install and to operate, CPM Wolverine Proctor Belt Coolers provide economical downstream product cooling for thermal processing lines. Specifically designed for permeable, static product beds.

SHREDDING MILL

The Shredding Mill is engineered and designed for future expandability. This high-capacity machine provides superior throughput while ensuring biscuit uniformity. Its Programmable Logic Controller (PLC) makes full automation possible and contributes to product uniformity and quality.

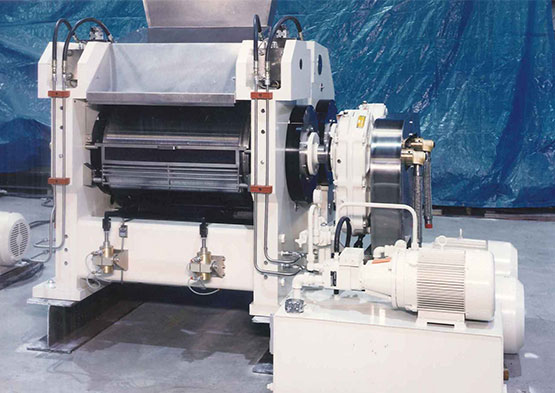

FLAKING MILLS

CPM Wolverine Proctor Flaking Mills have been designed to produce consistently superior flakes—every time. The Wolverine patented rolls are designed with multispiral grooves, ensuring that precise control of roll heat is generated during flaking.

LAUHOFF BATCH COOKERS

The Rotary Batch Steam Pressure Cereal Cooker delivers consistently cooked, milled, or whole grains necessary for the production of high-quality breakfast cereal flakes. Utilizing high-pressure steam and a unique double conical vessel shape, the unit delivers uniformly mixed and evenly cooked cereal grains with the highest degree of automation and sanitation available in the marketplace today.