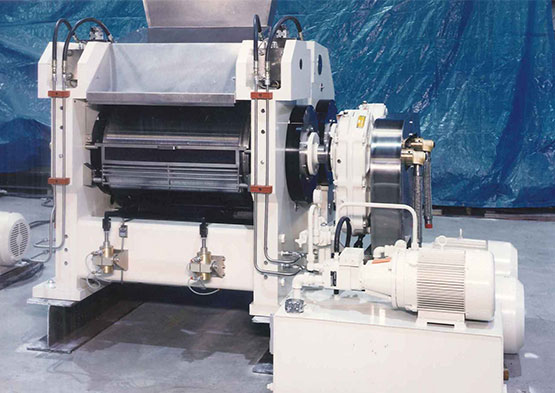

FLAKING MILLS & SHREDDING MILL LINES

FLAKING MILL

CPM Wolverine Proctor Flaking Mills have been designed to produce consistently superior flakes—every time. The Wolverine patented rolls are designed with multispiral grooves, ensuring that precise control of roll heat is generated during flaking. The multispiral grooves create turbulent coolant flow around the entire roll circumference at high flow rates. In conjunction with an automatic, programmable, closed-loop recirculated water cooling system, the patented rolls control roll surface temperature to within 1.5°F across a 40in-wide (1016mm) face. Roll heat buildup no longer limits capacity, eliminating sticking and flake thickness variation from roll distortion and hot spots.

FEATURES & BENEFITS

- Effective: Heavy, machined steel mill frame designed for low deflection and vibration

- Options: Independent fixed-speed roll drives or optional AC variable frequency drive package is available, with high-torque drives as standard equipment

- State-of-the-art: Pneumatically loaded stellite roll cleaning blades

- Minimal wear and tear: Controlled pre-set pressure adjustment minimizes blade wear

- Remote: Hydraulic power unit can be remotely located

- Efficient: Optional high-frequency pellet feeder separates and distributes each pellet uniformly for flaking, significantly reducing frequency of doubles

- Advanced: Optional preheating conveyor equipped with IR heating elements and stick-resistant conveyor designs

- Cost-effective: Low-cost hydraulic manual gap control system available

- Robust: Standard through-hardened roll shells permit many regrinds

- High-capacity: Highest capacity per applied power ratio available